Why Contractors Rely on MEP Coordination for Hospital Construction Projects?

===============================================================================

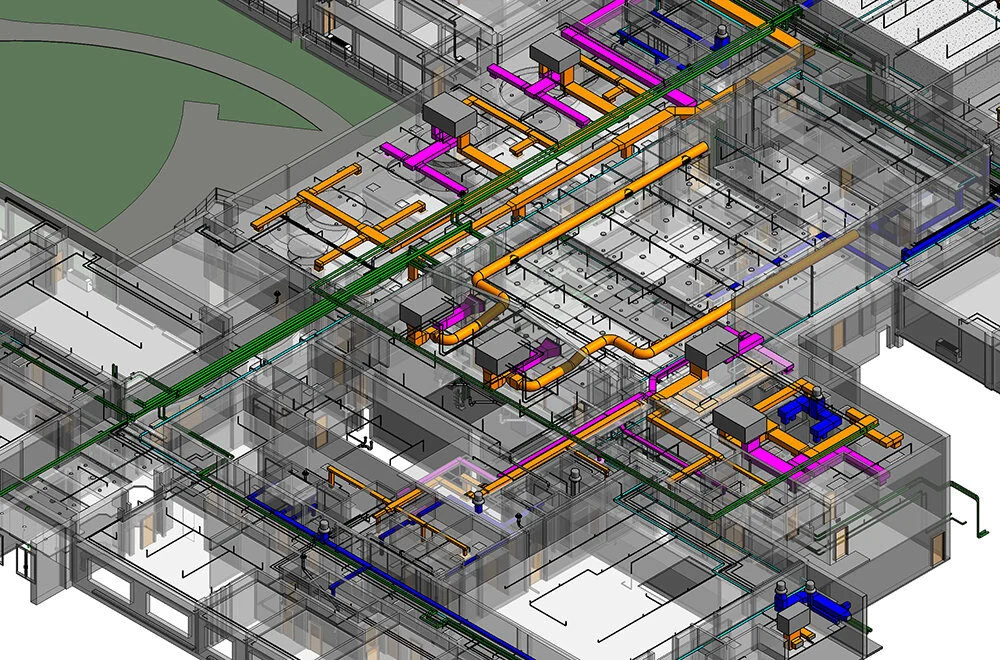

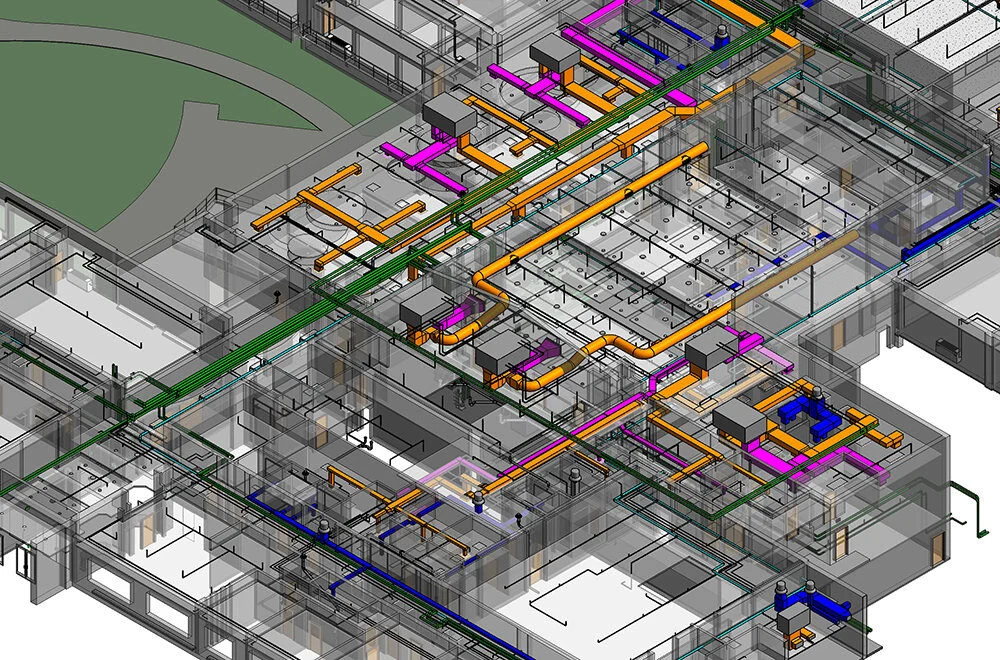

Hospital construction projects stand among the most complex in the AEC industry, demanding precision, strict compliance, and seamless collaboration across multiple disciplines. Unlike typical commercial buildings, healthcare facilities integrate highly specialized spaces such as operating rooms, intensive care units, diagnostic centers, etc., each with unique functional and safety requirements. At the core of these facilities lie Mechanical, Electrical, and Plumbing (MEP) systems, which are far more intricate than in standard buildings.

These systems ensure patient comfort, support life-saving equipment, maintain sterile environments, and provide uninterrupted utilities. Even a minor disruption or misalignment can compromise patient safety and operational efficiency. This is why MEP Coordination for Hospital Construction Project is mission-critical. By aligning designs, detecting clashes, and synchronizing installation sequences early in the project lifecycle, contractors can avoid costly rework, meet strict deadlines, and deliver healthcare environments that function flawlessly from day one.

Understanding MEP Coordination Services in Hospital Construction

MEP Coordination Services involve integrating Mechanical, Electrical, and Plumbing systems into a unified, clash-free design that aligns with architectural and structural elements. In a hospital construction project, the goal is to ensure every system function optimally, meets regulatory standards, and supports the facility’s critical operations without interference.

1. Scope of MEP Systems in Hospitals

- Mechanical (HVAC): Climate control, air filtration, and pressurization for patient safety.

- Electrical: Power distribution, emergency backup systems, lighting, and medical equipment support.

- Plumbing: Water supply, drainage, and specialized systems like medical gases.

2. Unique Requirements for Hospital MEP Systems

- Life Safety Systems: Fire alarms, sprinkler systems, smoke control, and emergency lighting.

- Critical Power Requirements: Redundant power for life-support and diagnostic equipment.

- Infection Control Considerations: HEPA filtration, isolation room pressurization, and air change rates.

- Specialized Medical Gas Systems: Oxygen, nitrous oxide, vacuum, and compressed air delivery.

3. Regulatory Compliance

Hospital MEP BIM Services must adhere to Joint Commission standards, NFPA codes, ASHRAE guidelines, and local building regulations, ensuring safety, reliability, and accreditation readiness.

Through precise MEP Coordination for Hospital Construction Project, contractors can minimize conflicts, meet compliance, and deliver hospitals equipped for uninterrupted patient care.

Unique MEP Challenges in Hospital Construction

Hospital projects present a distinct set of complexities that make MEP BIM Services essential for accurate planning and execution. Unlike standard buildings, healthcare facilities demand a dense and highly integrated network of systems to meet stringent operational and safety requirements.

Key MEP Challenges in Hospital Construction Projects

- High Density of MEP Services: Multiple layers of ducts, pipes, conduits, and cable trays must coexist in limited ceiling spaces to support advanced diagnostic machines, surgical lights, and monitoring devices.

- Complex HVAC Systems: Hospitals require specialized HVAC designs to maintain strict temperature, humidity, and air quality standards, including negative and positive pressure rooms for infection control.

- Redundant Electrical Systems: Continuous power supply is critical for life-support systems, imaging equipment, and surgical tools, necessitating backup generators, UPS systems, and dual feeds.

- Specialized Plumbing & Medical Gas Distribution: Piping networks must safely deliver oxygen, nitrous oxide, vacuum lines, and sterile water while ensuring zero contamination risk.

- Stringent Code Compliance: Designs must align with NFPA, ASHRAE, Joint Commission standards, and local healthcare codes to ensure patient safety and operational licensing.

By addressing these challenges through MEP BIM Services, contractors can detect clashes early, optimize layouts, and guarantee reliable system performance from day one.

Why MEP Contractors Depend on BIM Coordination for Hospitals

In a hospital construction project, precision and planning are not optional; they are essential. Hospitals are mission-critical facilities where system failures or delays can directly impact patient care.

Contractors rely on MEP BIM Coordination Services to manage the complexity, avoid costly disruptions, and ensure seamless execution.

1. Ensuring Zero Service Clashes

- Avoiding Physical Collisions: In hospitals, ducts, conduits, and pipes often compete for the same ceiling and shaft spaces. Without coordination, collisions can halt progress.

- Clash Detection Tools: Leveraging 3D BIM models and advanced clash detection services enables contractors to identify and resolve conflicts during the design stage, reducing field modifications.

2. Meeting Strict Project Deadlines

- Reducing Rework and Delays: Accurate pre-construction coordination helps plan installation sequences, minimizing unplanned downtime.

- Phased Construction for Renovations: In refurbishment projects, MEP layouts are coordinated to allow certain hospital zones to remain operational, avoiding complete shutdowns.

3. Achieving Compliance with Healthcare Standards

- Code Adherence: Compliance with NFPA, ASHRAE, and local healthcare building codes is vital to ensure safety, efficiency, and licensure.

- Meeting Accreditation Requirements: Designs must also satisfy Joint Commission and other accreditation bodies’ standards for operational readiness.

4.Optimizing Space Utilization

- Maximizing Patient-Care Areas: Through precise routing of services, contractors can free up valuable floor space for treatment and diagnostic functions.

- Supporting Modular Systems: MEP coordination facilitates the integration of prefabricated or modular assemblies, reducing on-site installation time.

5. Cost Control and Budget Adherence

- Minimizing Material Waste: Accurate layouts and prefabrication-ready designs prevent over-ordering and cut-offs.

- Reducing Change Orders: Early conflict resolution during the design phase limits unexpected expenses during construction.

By investing in MEP BIM Coordination Services, contractors can transform complex hospital construction into a predictable, efficient, and compliant process. The result is a facility that meets operational demands from day one, supports life-saving work, and is delivered on time and within budget.

Role of Technologies in MEP Coordination

Modern hospital construction projects leverage advanced technologies to make MEP Coordination more accurate, collaborative, and efficient. These tools not only streamline planning but also enhance execution quality and compliance.

Key Technologies Driving MEP Coordination

- Building Information Modeling (BIM) Applications: Enables the creation of intelligent 3D models that integrate mechanical, electrical, and plumbing designs. Supports clash detection, quantity take-offs, and simulation of system performance before installation.

- Virtual Reality (VR) for Design Review: Allows stakeholders to immerse themselves in a virtual hospital environment, visually verifying clearances, equipment placements, and patient flow before construction begins.

- Real-Time Collaboration Platforms: Cloud-based tools like Autodesk BIM 360 or Revizto enable contractors, engineers, and architects to share model updates instantly, reducing miscommunication and delays.

- Mobile Technology for Field Coordination: Tablets and mobile apps provide crews with up-to-date drawings, markups, and issue tracking directly on site, ensuring accurate installation.

- Quality Control & Documentation Systems: Digital inspection checklists and photo documentation ensure every MEP component meets standards and regulatory requirements.

By integrating these technologies, MEP coordination in hospital projects becomes more proactive, reducing risks while ensuring the facility is delivered on time and fully compliant.

Best Practices for Successful MEP Coordination in Hospital Projects

Effective MEP Coordination services in hospital construction require more than advanced tools; it demand a disciplined approach that aligns all stakeholders from concept to commissioning. Implementing the following best practices ensures accuracy, compliance, and efficiency.

- Early Stakeholder Involvement (Design-Build Approach): Engaging architects, MEP engineers, contractors, and facility managers from the early design stage fosters a shared vision, reduces design changes, and streamlines decision-making.

- Regular Coordination Meetings & Model Updates: Weekly or bi-weekly coordination sessions help track progress, address emerging clashes, and keep all parties aligned with the latest BIM model revisions.

- Using LOD 400+ for Fabrication-Level Details: Developing highly detailed models with fabrication-level specifications enables accurate prefabrication, minimizes site modifications, and improves installation speed.

- Incorporating Facility Management Data for Post-Construction Use: Embedding asset information, maintenance schedules, and system specifications into the BIM model supports long-term hospital operations and preventive maintenance.

By following these practices, contractors can enhance collaboration, avoid costly rework, and deliver hospital facilities that perform reliably from day one while meeting stringent healthcare standards.

Final Thoughts

MEP BIM coordination services are the backbone of successful hospital construction, ensuring that every mechanical, electrical, and plumbing system works seamlessly within the facility’s complex environment. By integrating MEP BIM Services and proactive collaboration, contractors can deliver functional, compliant, and efficient healthcare spaces that meet the highest safety and performance standards.

Beyond preventing clashes and meeting codes, effective MEP coordination for hospital construction projects plays a pivotal role in mitigating risks, reducing costly rework, and keeping projects on schedule. It also optimizes space utilization, supports advanced medical technologies, and ensures uninterrupted patient care from the day the hospital opens its doors. In an industry where precision directly impacts lives, MEP coordination is not just a project management tool; it is a strategic necessity that drives operational excellence and long-term value for healthcare providers.