The Future of Manufacturing: How CNC Technology is Shaping Industries

In the ever-evolving landscape of manufacturing, CNC (Computer Numerical Control) technology has emerged as a transformative force. From automotive to aerospace, CNC technology is revolutionizing industries by streamlining processes, enhancing precision, and increasing productivity. In this blog post, we’ll explore the myriad ways CNC technology is shaping industries, and how CNC companies in Alabama and beyond are at the forefront of this technological revolution.

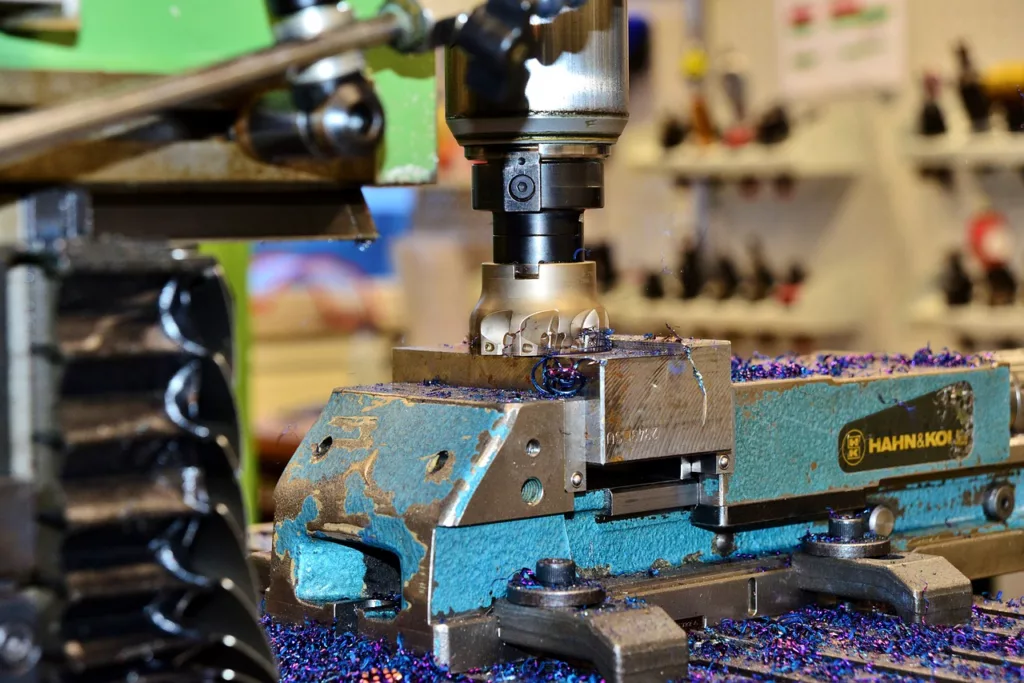

Redefining Manufacturing Standards

CNC technology has redefined precision engineering, setting new standards for manufacturing excellence. With CNC machines, manufacturers can achieve levels of accuracy and consistency that were once unimaginable. Every cut, every drill, and every turn is executed with unparalleled precision, ensuring that each component meets exact specifications. This level of precision not only enhances product quality but also reduces waste and improves efficiency throughout the manufacturing process.

Catering to Diverse Needs

In today’s market, customization is key to staying competitive. CNC technology empowers manufacturers to meet the diverse needs of their customers with ease. Whether it’s creating complex geometries or producing unique prototypes, CNC machines offer unparalleled flexibility and versatility. CNC companies near me are leveraging this capability to offer personalized solutions to their clients, driving innovation and fueling growth in various industries.

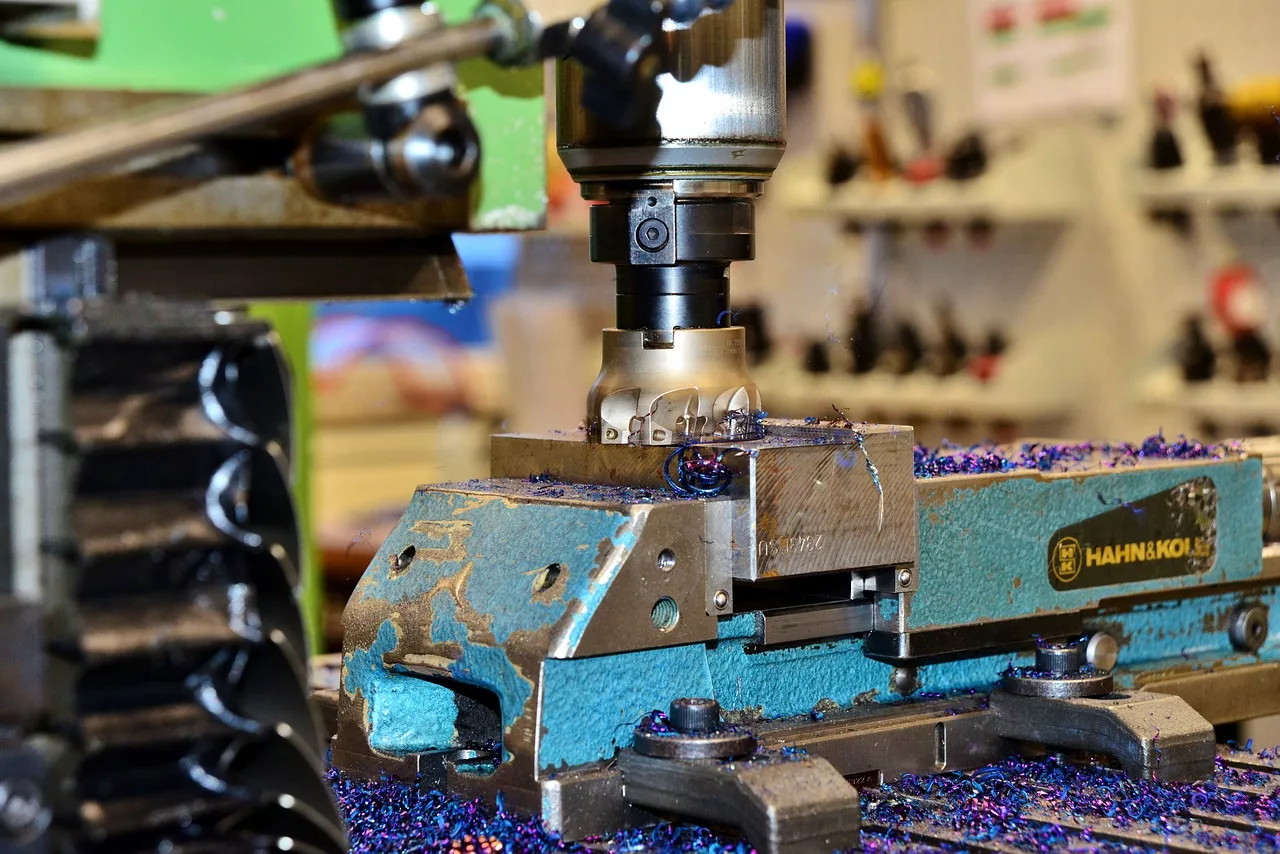

Optimizing Production Processes

Efficiency is paramount in manufacturing, and CNC technology is driving significant improvements in this area. By automating repetitive tasks and minimizing human error, CNC machines streamline production processes and reduce cycle times. This increased efficiency translates to lower production costs and faster time-to-market, giving manufacturers a competitive edge in today’s fast-paced business environment.

Pushing the Boundaries of Possibility

The adoption of CNC technology has opened up new possibilities in materials engineering. CNC machines are capable of working with a wide range of materials, from metals and plastics to composites and ceramics. This versatility enables manufacturers to explore innovative materials and push the boundaries of what’s possible. With CNC companies in Alabama leading the charge, industries are embracing advanced materials to create lighter, stronger, and more durable products.

Driving Industry 4.0 Initiatives

As industries embrace the principles of Industry 4.0, CNC technology is playing a central role in driving digital transformation. CNC machines are seamlessly integrated into smart manufacturing environments, where they communicate with other machines, sensors, and systems in real-time. This connectivity enables data-driven decision-making, predictive maintenance, and remote monitoring, leading to greater efficiency, reliability, and agility across the manufacturing value chain.

Reducing Environmental Impact

CNC technology is helping manufacturers reduce their environmental footprint by optimizing resource utilization and minimizing waste. With CNC machines, manufacturers can achieve higher material efficiency and energy savings compared to traditional manufacturing methods. By embracing sustainable practices, CNC companies are not only reducing costs but also contributing to a healthier planet for future generations.

Conclusion

In conclusion, CNC technology is revolutionizing industries by redefining precision engineering, enhancing customization, increasing efficiency, exploring advanced materials, driving Industry 4.0 initiatives, and promoting sustainable manufacturing practices. As CNC companies in Alabama and beyond continue to innovate and push the boundaries of what’s possible, the future of manufacturing looks brighter than ever. Embracing CNC technology is not just a choice; it’s a necessity for staying competitive in today’s dynamic marketplace.