Top 5 Types of Warehouse Shelving and How They Work

You need an efficient and streamlined warehouse, and to optimize your process flow, you need the right warehouse shelving. Some of the most important parts of your business depend on your ability to make a good decision in this regard. Without the proper shelving, you’ll fall behind the competition and problems will start to pile up.

To ensure you have perfect movement of goods and proper storage, throw down some cash to get the right stuff. In this blog, we’ll compare different types of warehouse shelving, so read on to get the goods!

Why Does Shelving Type Matter?

There are several factors other than sturdiness and size that come into play when choosing the right shelving type for your business. You need to consider braces, clips, accessibility, safety, and more. Make an informed decision to improve efficiency, practicality, and ultimately, your bottom line.

Warehouse Shelving Types Explained

Industrial shelving systems are designed to optimize safety and warehouse organization. The type of business you have will be a huge factor in determining the type or types, you’ll need. Whether you’re just starting out or you want to buy warehouse shelving as a replacement, consider these types:

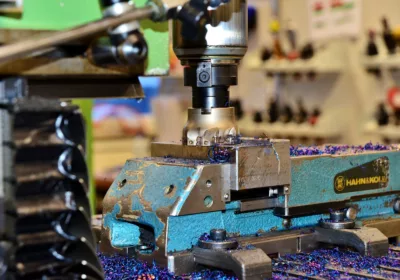

1. Steel Shelving

Store small items and cartons on steel shelving. It’s the most common type used today. This racking system can be used in high-rise, horizontal, or floor-level storage. Steel shelving has poor maneuverability, but it’s cheap, versatile, durable, and features compression clips for customization.

2. Rivet Shelving

While just as versatile and sturdy, rivet shelving is better for mobile storage. Built from steel and decking, they can hold a lot of weight and is perfect for large-scale warehouses with heavy items.

No clips or bolts mean easier assembly. It comes in many sizes but isn’t very customizable.

Pro tip: Buy your decking locally.

3. Wire Shelving

Wire shelving offers great air circulation, visibility, and hygiene. It’s easy to assemble and clean, and mounts on casters for mobility. Wire shelving fits into corners and nooks. This type is superior to wood for pallet racking because it’s both stronger and safer, minimizing workplace injuries.

4. Boltless Shelving

Boltless shelving, also known as “Clipless” shelving is good for industrial applications and is made of steel bracing and particleboard. It’s perfect for storing large, lightweight objects. It’s easy to build and a breeze to maintain, but it’s not as strong as rivet or steel.

5. Bulk Rack Shelving

If you are looking to maximize your space and need a heavy-duty shelving solution, choose a bulk rack. It’s durable and perfect for hand stacking boxes. Bulk rack shelving is boltless and mounts easily on casters, so it offers simple assembly and mobility.

Don’t Let Warehouse Problems Stack Up

Become more organized and efficient with new warehouse shelving. After all, you might have paid too much for your needs, or perhaps too little, sacrificing safety. Save money down the line and plan ahead for what the future might hold for your inventory, space, and accessibility needs.

If you enjoyed this article, read more of our blog!