Difference Between Square and Rectangular Seamless Tubes

Seamless pipe manufacturers produce tubes of different shapes. You will get multiple options when purchasing seamless tubes and pipes, from circular pipes to square and rectangular tubes. Pipe manufacturers use a series of dies to form the pipes from coils. To produce the shape of these tubes, manufacturers use internal welding.

Typically, you need rectangular tubes for structural and maintenance purposes. Building construction, railings, and truck frames are examples of applications for rectangular and square tubes.

However, there are differences between the two. You must evaluate them based on their outside measurements and wall thickness. These tubes are frequently available in hot-rolled, cold-rolled, stainless steel, carbon alloy, titanium, and aluminum. Top seamless tubes and pipes manufacturers are experts at creating tubes of the highest quality possible in accordance with industry standards. It can be trimmed precisely as per your requirements.

Square vs. rectangular steel seamless tubes:

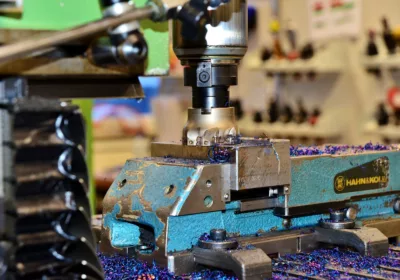

Pipe producers choose solid steel billets from which they produce square and rectangular tubes. They use hot rolled metal coils to pierce the billets with a cylindrical mandrel. Since stainless steel is widely available, the price of steel tubes is much lower than any other metal pipes. In addition, you get robust tubes that are durable, lightweight, and rigid with a greater strength-to-weight ratio.

Differences between square and rectangular steel tubes:

There are some significant differences between square and rectangular cold-drawn seamless tubes. The primary difference is that the cross-sections are as per the shapes of the tubes. So, while square tubes have square cross-sections, rectangular tubes have rectangular cross-sections.

Even in terms of application, you will notice differences between the two types of tubes. Square tubes are essential in the construction and manufacturing industries. Apart from these two, you can also see the wide use of square tubes in shipbuilding, the agriculture industry, petrochemical, and power plants, steel structure and power engineering industries, automotive chassis, boiler construction, pressure vessels, the aviation industry, bridges, oil storage equipment, glass curtain walls, highway railings, railways, etc.

On the other hand, you can see rectangular seamless tubes being used to transport different types of fluids, including steam, oil, water, natural gas, etc. In addition, rectangular pipes are widely used for manufacturing mechanical parts because they are lightweight, and their torsional strength is the same as their bending strength, making the tubes pliable. Also, investing in rectangular steel tubes is the best choice for you if you are in the engineering structure industry. Besides, you will also find the use of rectangular seamless pipes and tubes in weapon production, including producing shells, barrels, etc.

Since square tubes are a type of rectangular tube, you can replace rectangular tubes with square ones for some specific applications. For example, you can use both square and rectangular seamless tubes alternately for construction projects or boiler systems.

Uses of Square and Rectangular Seamless Tubes

The utilization of square and rectangular tubes has a myriad of purposes. Square tubes are commonly applied in the construction industry, machinery manufacturing, and steel construction projects. They are also utilized in shipbuilding, solar power brackets, steel structure engineering, power engineering, power plants, agricultural and chemical machinery, glass curtain walls, automotive chassis, airports, boiler construction, highway railings, building construction, pressure vessels, oil storage tanks, bridges, and power station equipment.

On the other hand, rectangular tubes are widely used in the transportation of various fluids, including petroleum, natural gas, water, gas, and steam, among others. Their lightweight quality makes them ideal for the production of mechanical parts and engineering structures, provided that bending and torsional strength remain constant. Rectangular tubes also find their use in manufacturing a range of conventional weapons, such as barrels, shells, and the like.

The last words:

Pipe manufacturers produce rectangular tubes primarily using two methods: cold and hot rolling. First, they roll the hot-rolled strip through a procedure to create the rectangular tube. Cold-drawn seamless tubes are cold-drawn or cold-rolled precision tubes with high dimensional accuracy and excellent surface polish for mechanical structures and hydraulic equipment.

The perforation process in the tube blank is a crucial step in the production of the square tubes since it is the source of many problems in the tube. The limited perforation performance of high alloys is a critical challenge. To make sure that you are getting quality products, you must ensure that the manufacturers choose the deformation parameters of the perforation carefully.