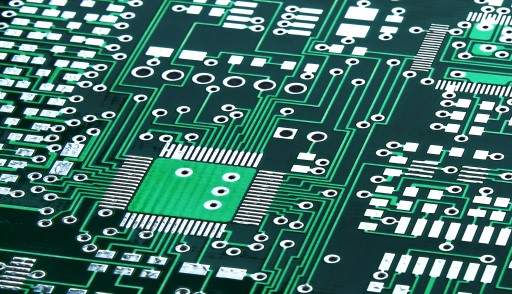

The Importance of Tolerances in PCB Manufacturing

The success of PCB manufacturing is dependent on the process’s dependability and consistency. Strict tolerances must be maintained throughout the manufacturing process to do this. Tolerance is the amount of acceptable deviation from a set value in the realm of PCB manufacture. A PCB trace width, for example, may have a tolerance of +/- 0.005 inches. This means that the trace’s width can vary by up to 0.005 inch. Tolerance is critical in PCB fabrication because it guarantees that components fit correctly and that the finished product functions properly. Tolerance can be affected by a number of factors, including material qualities, manufacturing processes, and design criteria. Tolerance is obviously crucial to the success of the PCB manufacturing process.

The criteria for printed circuit board (PCB) manufacture get more stringent as technology improves. To satisfy these standards, manufacturers must have a thorough understanding of the many components of PCB fabrication, as well as the tolerances required for each. In this post, we will look at the many components of PCB fabrication and the tolerances necessary for each.

A Reminder Before We Begin

Tolerances may differ across manufacturers. Precision in producing alignment holes, for example, will vary from maker to manufacturer. The same is true for the width of copper traces and the finished board thickness.

When fabricating a PCB, it’s critical to understand the manufacturer’s tolerance levels. This ensures that your board fulfills all of the required criteria and functions as intended.

Dimensional Tolerances on a Circuit Board

When creating a printed circuit board (PCB), there are numerous factors to consider. Each element, from the material to the design, must be carefully picked to ensure the final product is of high quality. But what exactly are the tolerances that must be met for a PCB to be successful? We will now look at the many components of PCB manufacture and the tolerances necessary for each.

Thickness of Circuit Boards:

Fabricating PCBs with the proper thickness is important to their performance. As a result, the tolerance, or permissible fluctuation in thickness, is a significant concern. There are two basic reasons why PCB thickness is important. The standard tolerance for PCB thickness is 10%. This indicates that the PCB can be up to 10% thicker or 10% thinner than required and still meet specifications.

Tolerance in Drilling:

Drilling a printed circuit board (PCB) is a crucial aspect of the manufacturing process, but it is also one of the most demanding and challenging operations. This is due to the fact that PCBs are exceedingly thin and delicate, and even the smallest error can wreck the entire board. That is why it is critical to drill PCBs with a high degree of tolerance. Tolerance is often expressed in terms of the width of the hole being drilled. A tolerance of +/- 0.005 inches, for example, means that the hole must be drilled within 0.005 inches of the intended width to be considered accurate.

Routing Tolerances:

When designing a PCB, it is critical to consider the board’s routing tolerance. The routing tolerance is the least amount of space that must exist on the board between two conductors. The circuit will not function properly if the spacing between the conductors is too small. The width of the traces, the spacing between the traces, and the thickness of the board are all parameters that might affect the routing tolerance of a PCB.

Copper Thickness:

In order for a PCB to function properly, the copper thickness on the board must be within a particular tolerance. Typically, this tolerance is plus or minus 10% of the required thickness. For example, if the specified thickness is 1 ounce, the tolerance is 0.1 ounce plus or minus. The copper thickness is significant because it determines the amount of current that can flow through the PCB. The current will be too low if the copper is too thin, and the PCB will not function properly. The current will be too high if the copper is too thick, and the board will be damaged.

The PCB industry has seen a commensurate increase in demand as a result of the recent expansion in the production of electronic gadgets. To achieve this requirement, it is vital to collaborate with a respected manufacturer capable of producing boards within the stipulated tolerances. To ensure that your products are capable of meeting the industry’s continuously changing requirements, you must collaborate with a team of professionals with relevant experience.

While many PCB manufacturers in USA claim to be able to achieve tight tolerance levels, not all of them have the necessary technology or experience to produce high-quality products on a constant basis. This is why it’s critical to conduct your research and select a partner you can rely on to build your boards with the finest precision, such as Twisted Traces.