What Are Subassemblies?

Have you ever wondered what subassemblies are and why they’re necessary?

As you might have guessed, subassemblies are smaller units within a larger product. It does not matter what product it is. It can be a motor vehicle or a piece of industrial equipment, but it is still made of subassemblies.

But what good are subassemblies, and how do end users or manufacturers see their value in them? That’s what we’re here to answer today.

Keep reading below to learn all about subassemblies.

What Are Subassemblies?

Subassemblies are parts assembled and used to build more complex assemblies. This can be anything from screws, nuts, washers, and bolts, to motors and other machine parts.

In the engineering world, subassemblies are the building blocks of a larger product. This includes cars, bicycles, robots, and spacecraft.

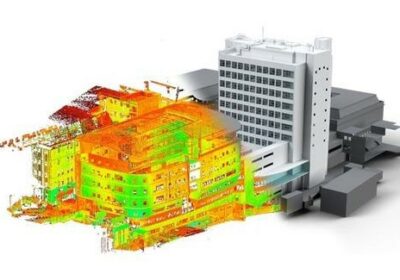

Manufacturers create subassemblies by combining many components into one unit. These components are building blocks. They are easier and quicker to integrate into the required assembly.

Subassembly building blocks are the parts or components that makeup subassemblies. This could include individual pieces of metal, wiring harnesses, and brackets. They follow a specific order to form a single assembly that a system can use.

Building subassemblies involves understanding the details of each component. Any value added distributor can provide parts. These parts are then combined in a modular design.

Benefits of Subassembly Design and Production

Subassemblies allow manufacturing teams to produce the components or parts quicker. They do not need to start from scratch every time.

Subassembly design and production also increase production in a shorter amount of time. This can help save the company money in the long run.

Additionally, modular subassemblies are ideal to help increase design flexibility. Parts can be interchangeable and combined to create a one-of-a-kind product. They also create less waste and use fewer resources than traditional methods.

It helps create a more cost-effective production system. And it also ensures efficient and effective product delivery.

What Makes an Effective Subassembly?

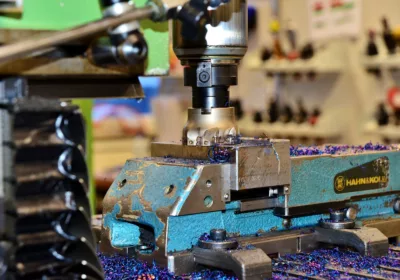

To create effective subassemblies, they must have a strong construction. They should also be accurate. Parts associated with the subassemblies need to fit together. They should also be able to handle any load necessary.

Manufacturers need to choose the proper materials, finishes, and coatings. These protect the subassemblies from corrosion and other environmental factors.

Implementation of quality control procedures is also necessary. The policy ensures that all subassemblies meet safety, durability, and performance standards.

The manufacturing processes should also be well-planned, organized, and documented. This allows for consistent and reliable production of subassemblies.

Learning More About Subassemblies Today

Subassemblies are a fantastic way to speed up assembly times. They reduce costs and simplify design tasks. They also ease production and can make assembly lines run better.

This is a great way for businesses to optimize their operations. They can still maintain high-grade standards while making more money. If you want to learn more about subassemblies, contact a subassemblies professional today!

Was this article helpful? Then check out the rest of our site for more informative posts like this.